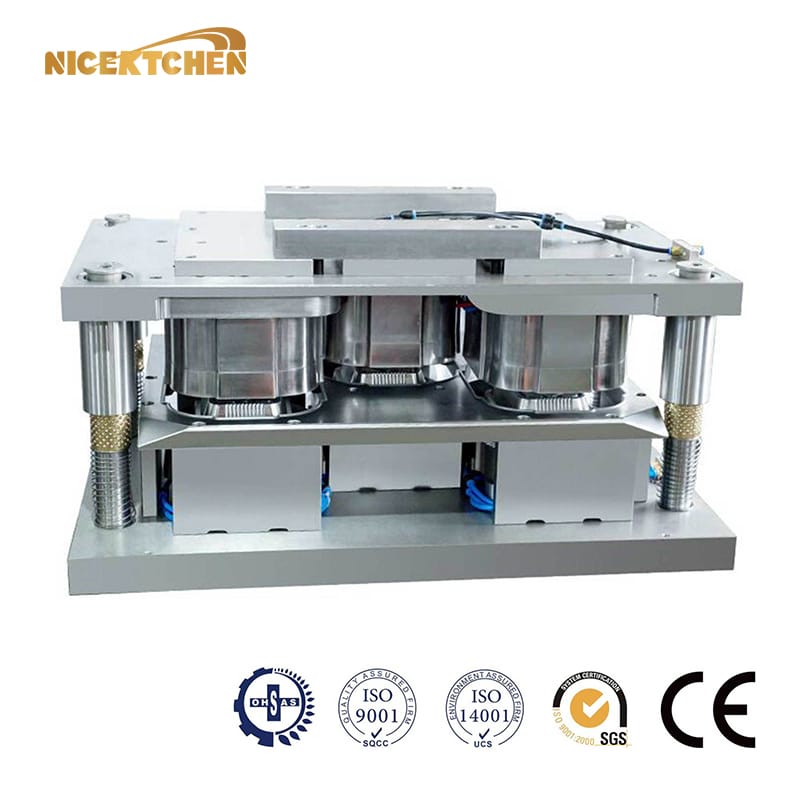

Al-foil container composite single-pass formong mould

Function

Our company base on lnternational and national monld’s feature,to develop and manufocture new type of composite single-pass formong mould.

Product Features

1、Adopt imported or national alloy steel material to make sure mould run in high speed.

2、Mould’s structure design properly, air channel design properly,also have lubrication system.

3、Adopt high frequency or spread on carbon processing workmanship highy,so that extend mould’s work life.

4、Adopt special processing style to produce mould in different shape.

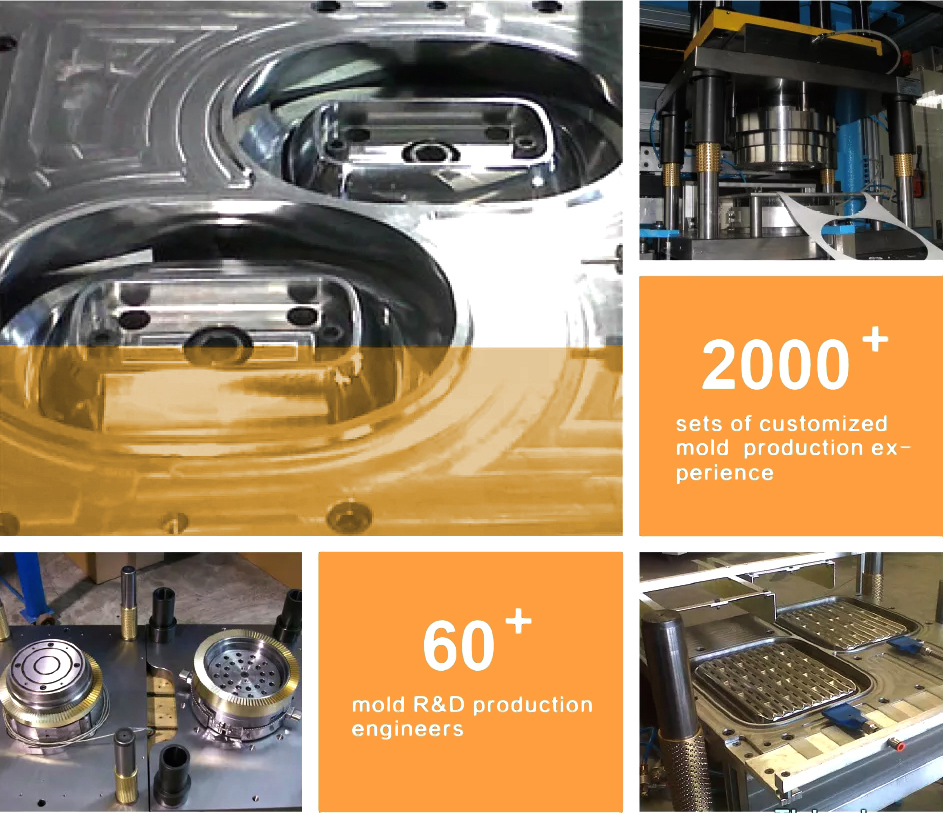

Technical data when customize mould

| Cpacity | Dimension of working table | Dimension of slider’s undersurface |

Dimension of die shank |

| Stroke of slider | Throat depth | Closed height | Adjustment of closed height |

Die Description:

◆ According to the characteristics at home and abroad, our company independently develops and manufactures the latest composite single pass forming die, which has the following characteristics:

◆ Domestic or imported alloy steel is used to ensure high speed operation of the die.

◆ There are professional air circuit design and lubrication system.

◆ High carbon or high frequency processing technology is adopted to prolong the service life of the die.

◆ We use special processing metho ds to make various shapes of molds.

◆ Die forming principle The upper die moves down to the cutting male die, cuts the female die, and the upper die maintains

◆ When moving down, the blank holder and the cutting punch generate BHF under the action of the lower cylinder, and the first-order drawing is realized under the action of the upper die core and the lower die core.

◆ The first stage drawing die continues to move, and the second stage drawing die realizes the second level drawing, and at the same time, the product label is pushed out.

◆ Punch pressure exceeds bottom dead center. The blank holder ring and the first stage female die form a rolling ring space under the action of the lower cylinder body to roll the products into a circle and continue to go up. The lower cylinder ejects the product and blows away the mold under the action of the blower.

Our company based of nathional or oversea’s feature,research and develop ourself,and manufacture the lastest composite sing-pass forming die,have the below features:

We adopt domestic or imported alloy steel,make sure mould can run in high speed.

Mould frame in professional design, air channel design specially,and with lubricating system inside.

We adopt high frequency or spread on carbon high processing workmanship,so that extend mould’s working life.

We adopt special processing methods to make out various shape of mould.

Principle of mould forming

upper mould moving down to cutting male die , and cutting female die to cut the material, upper mould keep

moving down, blank holder and cutting male die produce blank holder force in the action of below cylinder,and realize first level stretching in the action of upper mold core and below mold core.

First level stretching female die continue to move,to realize the second level stretching with the second level stretching male die,ejector makes sign on products at the same time.

Punch pressure pass the below deadpoint. blank holder and the first level female die to form a roll round space in the action of below cylinder,rolling products into round and continue go up,the below cylinder eject products out,and blow away from mould in the action of blower.